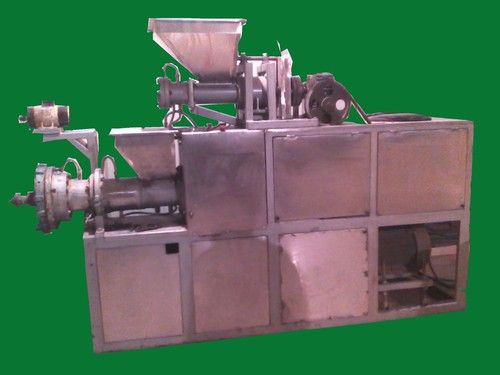

Continuous Masala System

Price 350000 INR/ Set

Continuous Masala System Specification

- Operating Temperature

- Ambient to 60C

- Heating Method

- None

- Phase

- Three Phase

- Automation Grade

- Automatic

- Frequency

- 50 Hz

- Features

- Hygienic Operation, Continuous Processing, Low Manpower Requirement

- Feeding System

- Screw Feeder with Hopper

- Machine Type

- Masala Mixing System

- Noise Level

- < 60 dB

- Speed Mode

- Variable

- Function Type

- Mixing & Coating

- Power Source

- Electric

- Product Type

- Seasoning System

- Material

- Stainless Steel

- Type

- Continuous Masala Applicator

- Weight (kg)

- 1850 kg

- Product Shape

- Rectangular Modular Structure

- Computerized

- Yes

- Automatic

- Yes

- Control System

- PLC Based Control

- Installation Type

- Floor Mounted

- Voltage

- 415 V

- Power

- 15 kW

- Dimension (L*W*H)

- 7200 x 1600 x 2450 mm

- Raw Material

- SS304 Food Grade

- Color

- Silver

Continuous Masala System Trade Information

- Minimum Order Quantity

- 01 Set

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 100 Sets Per Week

- Delivery Time

- 1 Week

- Main Domestic Market

- All India

About Continuous Masala System

With the assistance of our wide distribution network, we have been able to manufacture and supply the array of Continuous Masala System. Considered as the dryer cum masala machine, our range is widely used for providing coating to the namkeen with varied mouthwatering flavors. Always kept in hygienic places, these machines are demanded across many snacks companies. Moreover, the collection of Continuous Masala System is quality tested to ensure its long lasting attributes.

Features:

- Energy efficient

- Maintenance free

- User friendly

Specification

|

Minimum Order Quantity |

1 Piece |

|

Size |

24 Feet |

|

Snacks Type |

Namkeen |

|

Type Of Machines |

Fully Automatic |

|

Material |

S.S.Body |

|

Automation Grade |

Automatic |

|

Condition |

New |

|

Design Type |

Customized |

|

Model |

Seasoning Systems |

|

Brand |

ASE |

|

Capacity |

200 kg |

Advanced Modular Design for Robust Performance

Constructed with a rectangular modular structure, the Continuous Masala System incorporates high-grade SS304 stainless steel, optimizing both strength and hygiene. Its design makes it suitable for floor installation in diverse industrial settings, ensuring stable, reliable, and efficient masala mixing operations.

Automated PLC-Based Operation for Precision and Efficiency

The system utilizes a PLC-based control mechanism for seamless, automatic operation. With computerized management and variable speed settings, it delivers precise masala mixing and coating, minimizes human error, and streamlines continuous processing for optimal production outcomes.

Hygienic and Efficient Continuous Processing

Designed for the rigorous demands of modern food manufacturing, the machine features a screw feeder with hopper, supporting uninterrupted, hygienic mixing. The fully enclosed system limits contamination and keeps noise levels below 60 dB, creating a safe and clean working environment.

FAQs of Continuous Masala System:

Q: How does the Continuous Masala System enhance mixing efficiency?

A: The Continuous Masala System uses a fully automated, PLC-based control system and a screw feeder with hopper to provide consistent, uninterrupted masala mixing and coating. Its variable speed mode ensures optimal blending and uniform coverage, greatly improving process efficiency.Q: What is the benefit of using SS304 food-grade stainless steel in this system?

A: SS304 food-grade stainless steel ensures superior hygiene, corrosion resistance, and durability, which are critical for food processing applications. This material helps maintain product quality and extends machine longevity.Q: When is this system most appropriate for use in food production?

A: This system is ideal for operations requiring continuous spice mixing and coating, such as in snack, ready-to-eat, or convenience food manufacturing lines. Its automation and continuous processing capabilities make it suitable for high-volume production environments.Q: Where can the Continuous Masala System be installed?

A: The system is engineered for floor-mounted installation in industrial food processing environments. Its robust build and dimensions (7200 x 1600 x 2450 mm) require sufficient floor space and access to a three-phase, 415V power supply.Q: What is the process flow for mixing and coating spices using this system?

A: Raw ingredients are loaded via the hopper and screw feeder, which transfers them into the mixing chamber. Automated controls manage speed and flow, while the system continuously mixes and coats ingredients with masala, ensuring even distribution throughout the process.Q: How does this system minimize manpower requirements?

A: Thanks to its automated and computerized design, the Continuous Masala System significantly reduces the need for manual intervention, allowing a single operator to monitor multiple machines or focus on other production tasks.Q: What are the primary advantages of choosing this continuous system over traditional batch mixers?

A: This system offers continuous operation, better hygiene, consistent product quality, reduced labor costs, and lower contamination risks, making it more efficient and suitable for large-scale manufacturing compared to traditional batch mixing methods.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Food Processing Plants Category

PUFF RING Machine

Price 265000.0 INR / Set

Minimum Order Quantity : 1 Set

Automatic : Yes

Product Type : Industrial Machine

Material : Stainless Steel

General Use : Ring manufacturing

Kachri Machine

Price 265000.00 INR

Minimum Order Quantity : 1 Set

Automatic : No

Product Type : Food Processing Machine

Material : Stainless Steel

General Use : Food Processing

Vermicelli Machine

Price 650000.00 INR / Set

Minimum Order Quantity : 1 Set

Automatic : Yes

Product Type : vermicelli machine

Material : Stainless Steel

General Use : Food Processing

Batch Mixer

Price 45000 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic : No

Product Type : Batch Mixer

Material : Stainless Steel

General Use : Food Processing

Send Inquiry

Send Inquiry